Friction

welding

In this blog, we are going to learn about friction welding

What is friction welding?

Definition: It is

a type of solid-state welding in which the joining of two metals is produced by

heat generated through metal friction. The parts are held together under

pressure.

Process

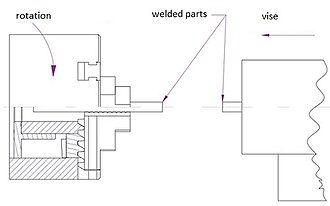

Explanation: In friction welding one part is either

rotating at high speed (circular shaft like job) or oscillating about its means

position (square or other non-circular shape) under a pressure held against

other part while other parts is held stationary. Due to high friction

generation all friction energy is converted into heat. The surface is heated by

this method till it reach its melting temperature when it reached its melting

temperature the relative motion between the job is stopped. This complete the

friction welding process.

Advantage of friction welding process:

1. 1.Low weld time

2. 2.Small heat affected zone compare to other conventional welding process

3. 3.Variety of metal and combination of metals can

be welded by this method

4. 4.High quality of welding can be achieved by this

method (google why nasa prefer friction welding for there jobs)

5. 5.Initial capital cost is low

6. 6. This process weld the whole surface contact in

case of electric arc welding only peripheral welding is done but In this case

whole surface is welded

7. 7.After welding further heat treatment might not

required

0 Comments

if you are not getting it then ask i am glad to help