What is Orifice Plate or Orifice Meter , Its construction , working and Industrial Application

What is Orifice Plate / Orifice Meter ?

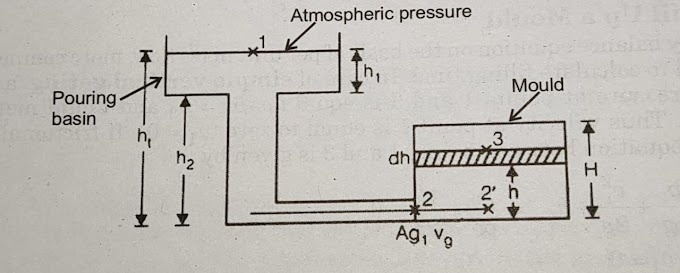

An orifice plate or Orifice Meter is a thin, flat plate with a centrally located hole or orifice. It is typically installed in a pipe or duct to measure the flow rate of liquids, gases, or steam. The size of the orifice, along with the pressure difference across the plate, is used to determine the flow rate according to established equations.

The principle of operation of an orifice plate is based on the concept of flow restriction and the application of Bernoulli's equation.

When fluid flows through the orifice, it experiences a constriction, leading to an increase in fluid velocity and a decrease in pressure. This pressure drop across the orifice plate is directly related to the flow rate of the fluid.

The formula for fluid rate is shown

Here `C_{d}` is the coefficient of discharge

`A_{1}` is the area of the pipe

`A_{0}` is the area of the orifice

`h` is differential head

Industrial Application of Orifice meter orifice plate

- Oil and Gas Industry: Orifice plates are used to measure the flow rate of natural gas, crude oil, and refined petroleum products in pipelines. They are crucial for custody transfer and monitoring purposes.

- Chemical Industry: Orifice plates are used in chemical processing plants to measure the flow rate of various chemicals and solvents. They are also used for controlling the flow of reactants in chemical reactions.

- Water and Wastewater Treatment: Orifice plates are used in water treatment plants to measure the flow rate of water and wastewater. They help in monitoring the efficiency of treatment processes and controlling the flow of water through different stages of treatment.

- Power Generation: Orifice plates are used in power plants to measure the flow rate of steam and other fluids used in the generation of electricity. They help in optimizing the efficiency of power generation processes.

- HVAC Systems: Orifice plates are used in heating, ventilation, and air conditioning (HVAC) systems to measure the flow rate of air and other gases. They help in maintaining proper indoor air quality and temperature control.

- Food and Beverage Industry: Orifice plates are used in food processing plants to measure the flow rate of liquids such as milk, juices, and beverages. They are also used in breweries and distilleries for measuring the flow rate of liquids during production.

Orifice meter v/s Venturi meter

- Cost: Orifice plates are generally less expensive to manufacture and install compared to Venturi meters. This makes them a more cost-effective choice for applications where budget is a concern.

- Space Limitations: Orifice plates require less space for installation compared to Venturi meters. In applications where space is limited, such as in retrofitting existing piping systems, an orifice plate may be preferred.

- Maintenance: Orifice plates are simpler in design and have fewer components compared to Venturi meters. This makes them easier to maintain and less prone to clogging or fouling, especially in applications where the fluid carries solid particles or debris.

- Flow Range: Orifice plates can be used over a wide range of flow rates, making them suitable for applications where the flow rate may vary significantly. Venturi meters, on the other hand, are more suitable for applications with a relatively constant flow rate.

- Accuracy Requirements: While both orifice plates and Venturi meters can provide accurate flow measurements, Venturi meters are generally considered more accurate, especially in applications where high precision is required.

.webp)

0 Comments

if you are not getting it then ask i am glad to help