PATTERN ALLOWANCE IN CASTING

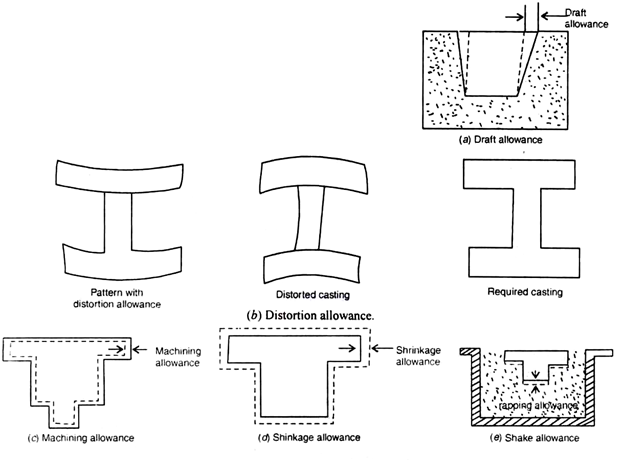

SHRINKAGE ALLOWANCE:

We all know that molten metal shrinks during the solidification process and it will contract further during room temperature. Due to this reason dimensions of the pattern are bigger than the actual size of the casting.In simple words, if you make the casting size of exact dimensions as you required in pattern and does not give shrinkage allowance you will get less accurate / size difference between the actually you getting and actually you want. This is called "Shrinkage Allowance".Shrinkage allowance is given by mm/m (millimeter of shrinkage per meter). Normally Shrinkage allowance of some material

- Brass = 15 mm/m

- Steel = 20mm/m

- Malleable Iron = 10mm.m

MACHINING ALLOWANCE:

Whenever we do normal casting we get poor surface finishing or casting size is larger than the requirement so that we can use various Machining operation to achieve the desired product the allowance provide to do these on the casting product is called Machining allowance.

The machining allowance depends upon various kind of things

- Material

- Size

- Method of production to produce casting

- Volume of the production

- Accuracy and precision of product

PATTERN DRAFT/ TAPER ALLOWANCE :

Draft or taper allowance is provided so that pattern can be removed from the mould cavity without damaging it . The draft of taper allowance is usually in the range of 1 to 3 degree

CORNER AND FILLETS:

All the corner of the pattern whether it is inside the pattern or outside the pattern they must suitably round or provide fillets. This fillet or roundness is provided to prevent the formation of shrink holes and crack in the casting

DISTORTION ALLOWANCE :

This kind of allowance is provided on complex or irregular shapes . During cooling these kind of shape do metal shrinkage and give unwanted result to protect it we provide distortion allowance

0 Comments

if you are not getting it then ask i am glad to help