SHRINK FIT ANALYSIS IN SOLIDWORKS

what is shrink-fit?

Shrink fit basically means fitting a part into a slightly small hole or cavity . since this can be done by force only so stress generate

what are the shrink fit analysis where they are used?

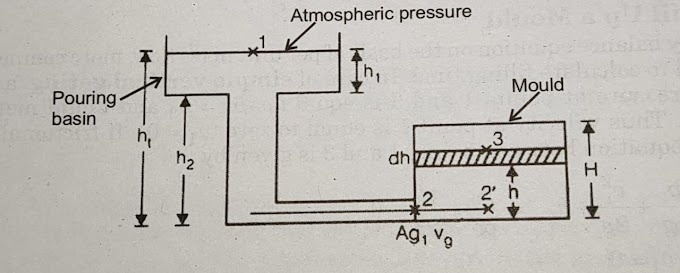

the most common example is fitting a shaft into a hole. here if you make your shaft COLD (Liquid nitrogen is normally used) it diameter will reduce (thermal expansion and compression thing). since your dia is now smaller than hole you can place into the hole . after sometime your shaft will come to normal temperature so the diameter try to increase and shaft will be tightly it in hole . now the expansion it can't able to do it (hole diameter is less than shaft so when shaft try to reach its original diameter it will face compressive stress). due to that stress will generate and in this article we are going to learn how to calculate that stress

Step1 . make an assembly make sure that interference is occurring (shaft dia > hole dia)

step2. Assign the material to your shaft and hole as per the requirement. (i apply plain carbon steel)

step 3. Now go to fixture and click select the bottom as shown in pic and make it fixed

0 Comments

if you are not getting it then ask i am glad to help